Thanks for the info. Naturally, one of the first things in problem solving is to know what the problem is. Of course you can accidently solve it by implementing a solution that happens to be the fix, but then it is more a matter of luck.

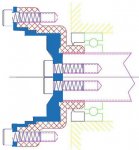

Anyway, taking your image (nicely done), this is something that goes through my mind. What if the "washer" was more like a pie pan and went all of the way out so that it was also secured by the six bolts holding the half-shaft to the axle (sandwiched in) plus the two main bolts. This would probably eliminate washer problems. Shear would be a different matter.

The other thought I had was what if there were some small nipples on the back of the washer that would center in to slightly tapered bolt holes in the axle (small countersink).

Last idea was a pin through the washer that would engage the splines so that there would be a plane (three points) instead of the two.

Anyway, taking your image (nicely done), this is something that goes through my mind. What if the "washer" was more like a pie pan and went all of the way out so that it was also secured by the six bolts holding the half-shaft to the axle (sandwiched in) plus the two main bolts. This would probably eliminate washer problems. Shear would be a different matter.

The other thought I had was what if there were some small nipples on the back of the washer that would center in to slightly tapered bolt holes in the axle (small countersink).

Last idea was a pin through the washer that would engage the splines so that there would be a plane (three points) instead of the two.