Horsepower is an imprecise measure of rod strength. Manley cites approximate HP in the catalog image, but caveats that with some of the other variables.

For our engines, being significantly undersquare, rpm may be more of a limiting factor than hp. For such a long stroke design, the 6,500 rpm redline is remarkable and generates insane piston speeds.

The stock rods seem to handle 800 hp ok. We've seen enough Whipples and TTs with stock bottom ends. But while 800 hp at under 6,500 rpm may be ok, far less hp may result in rod failure at over 6,500 rpm.

Boost is another tricky variable. Keep in mind that our stock blowers use 80 hp at full boost. A big Whipple will need well over 100 hp. So, a big Whipple motor needs to make well over 900 hp to put 800 to the output shaft and 7xx to the wheels.

The GT500 websites are full of broken and bent rod photos.

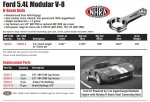

View attachment 37761

BTW, that's an I-beam, but I can't say for sure that it came from a 5.4 GT500.

And, who's to say the rod was too weak for the hp? Maybe the tune was to blame. Or over-revving. Ford was comfortable enough to put the same (or similar) rods in the 5.8 and put a factory warranty on 662 hp.