I am having a difficult time posting pictures (not very computer savy) so please bear with me over the next couple of days while I slowly load the pictures of the insides of the Ford GT gearbox.

In 2006 Team STILLEN went to the New Zealand Targa Rally with the now famous orange Ford GT. 2006 was really just a practice year and we only wanted to learn what we could change and what the car would benefit from. During the development of the car Steve Millen spoke directly with many of the engineers from the GT project and learned that during testing there was actually a 3.90 gear ratio developed for the car. We also learned that the main reason the car comes from the factory with the 3.3 is because marketing did not want any of the magazine's messing up the 0-60 times and with the factory gear ratio you don't need to shift until 62 MPH anyways. However, the engineers liked the increased performance of the 3.90.

Well, a couple of years later and after much development with Ricardo, STILLEN became the only company in the world authorized by Ricardo to work on and service the Ford GT transaxle. We worked very closely with Ricardo to develop the 3.90 ring and pinion and after our initial batch came in with a very aggressive cut we had them all sent back out for polishing and grinding to eliminate as much gear whine as possible. Some owner's will notice that some cars (not all) experience a little bit of whine from the factory, the 3.90 is no different. Some cars make the whine, some cars don't.

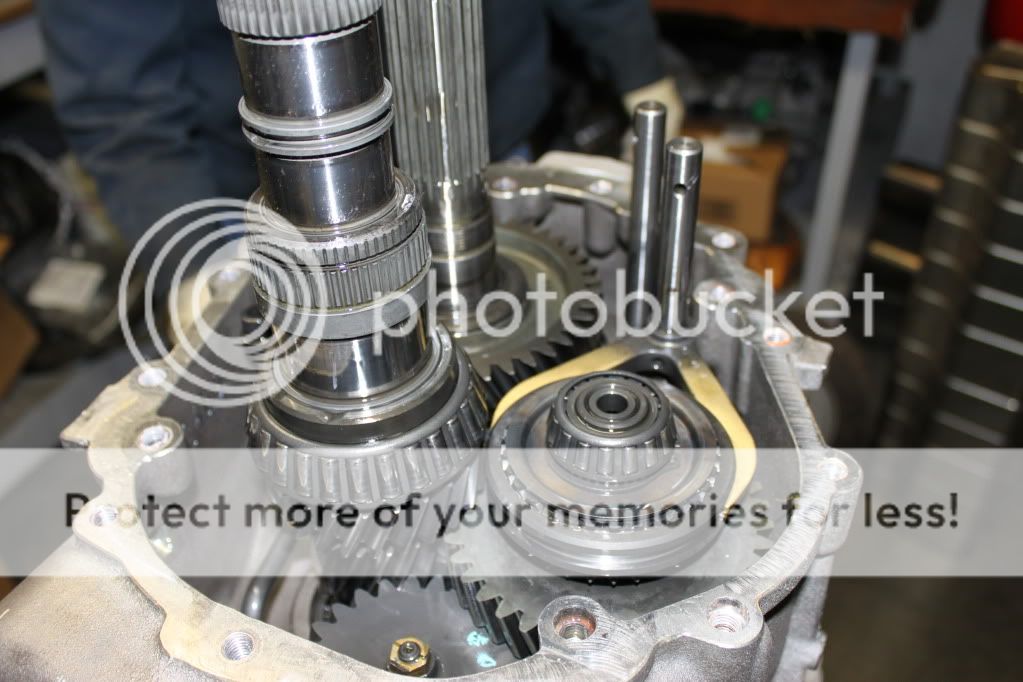

Part of the development program for the 3.90 included specialized training from the engineer who developed the Ford GT gearbox. He flew in from England and trained our technicians on the ins and outs of the transaxle. How to strip it down, what to look out for, what to be careful of, and how to rebuild it. It was at this time that we learned that we would need to custom fabricate and machine 7 specialized tools in order to properly and safely disassemble the transaxle.

There were 25 sets of ring and pinions made for us. When the initial 25 were sold we went back to Ricardo and asked what it would take to make another 10 and we also asked for a discount as the cost of steel had dramatically gone down. Unfortunately, Ricardo decided they did not want to make them again and required a minimum of 25 pieces, 50% of the money down to start, then another 50% due upon completion and they were going to raise the cost 30%. We did not feel that the market could stand for a 30% mark up on a part that was already pretty pricey. So, unfortunately, for the time being, there are no immediate plans for another production run of ring and pinions.

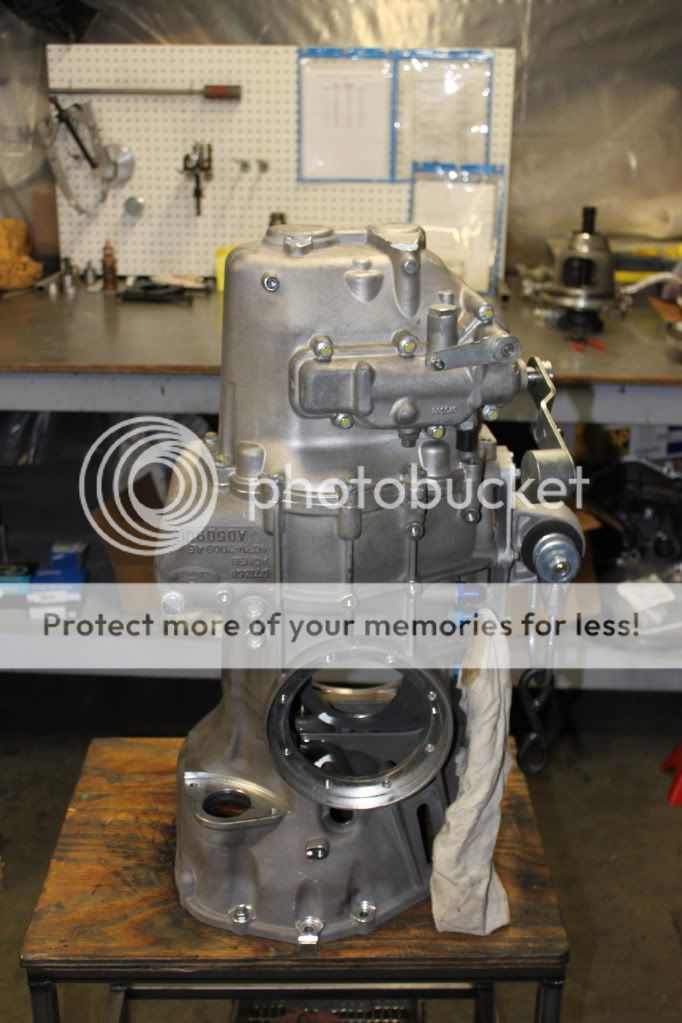

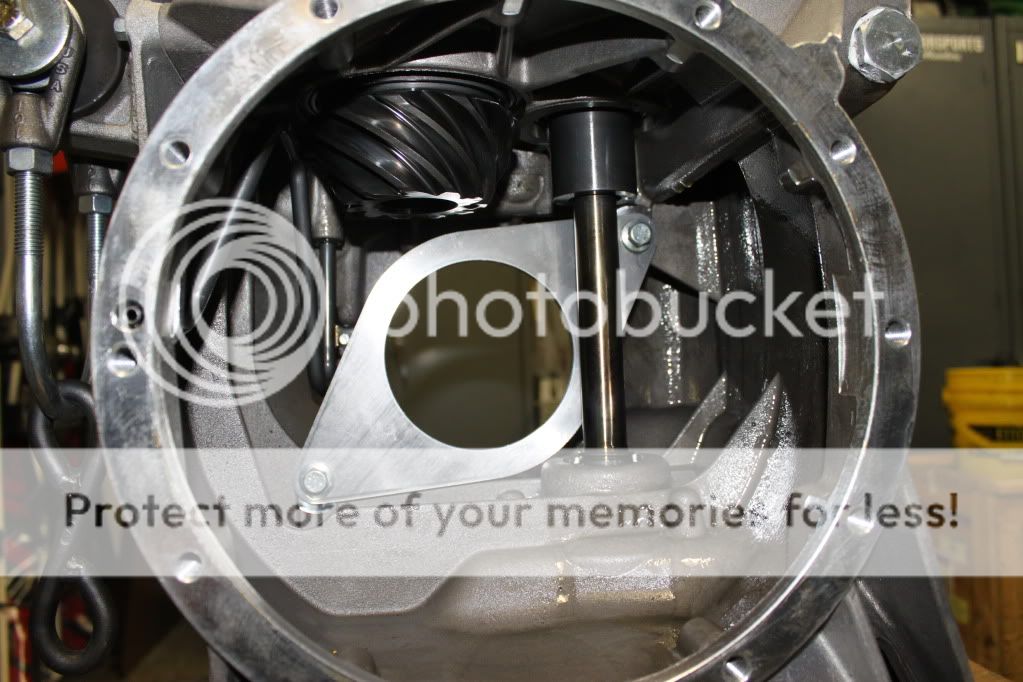

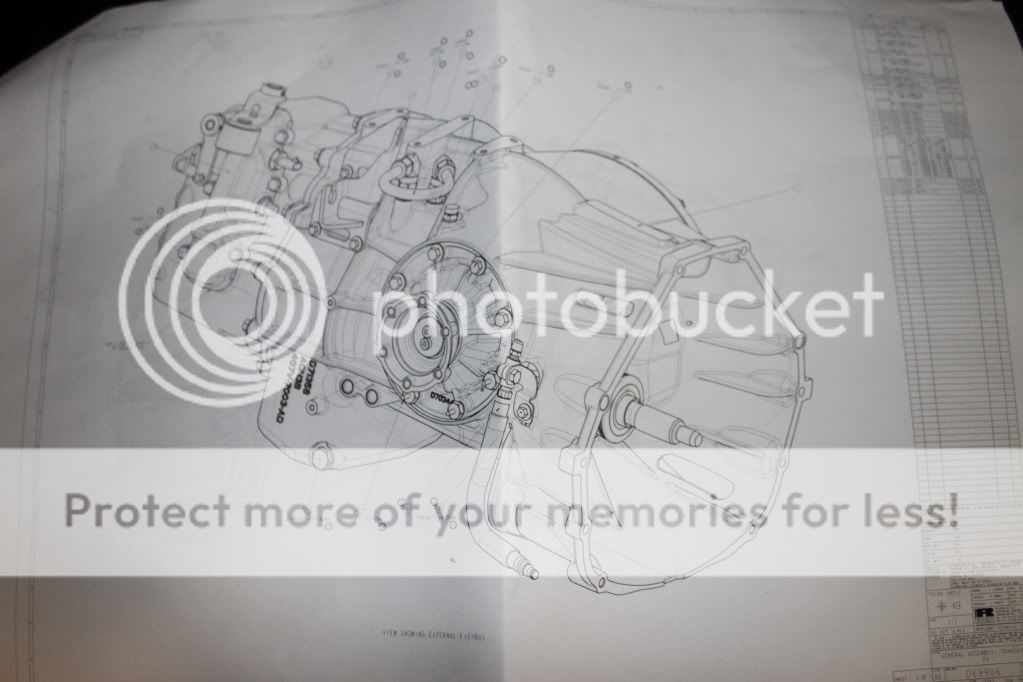

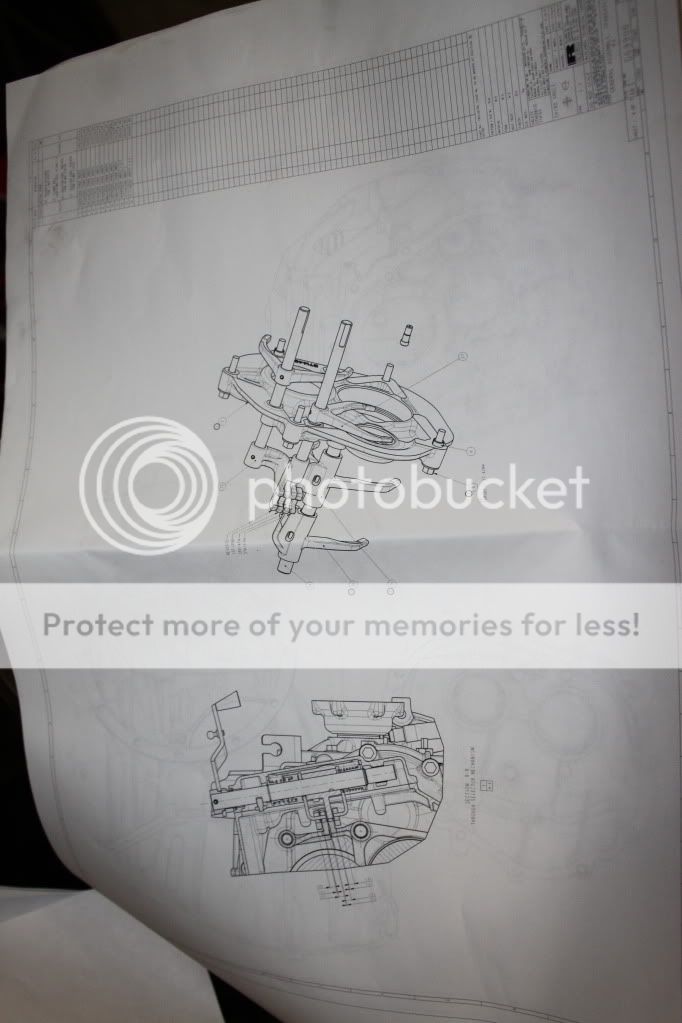

So, as requested by one of the forum member's. Here are a few pictures of the inside of a Ford GT transaxle. Please keep in mind that I will be posting more pictures over the next couple of days.

To start with: The engineer from Ricardo who trained us on the installation:

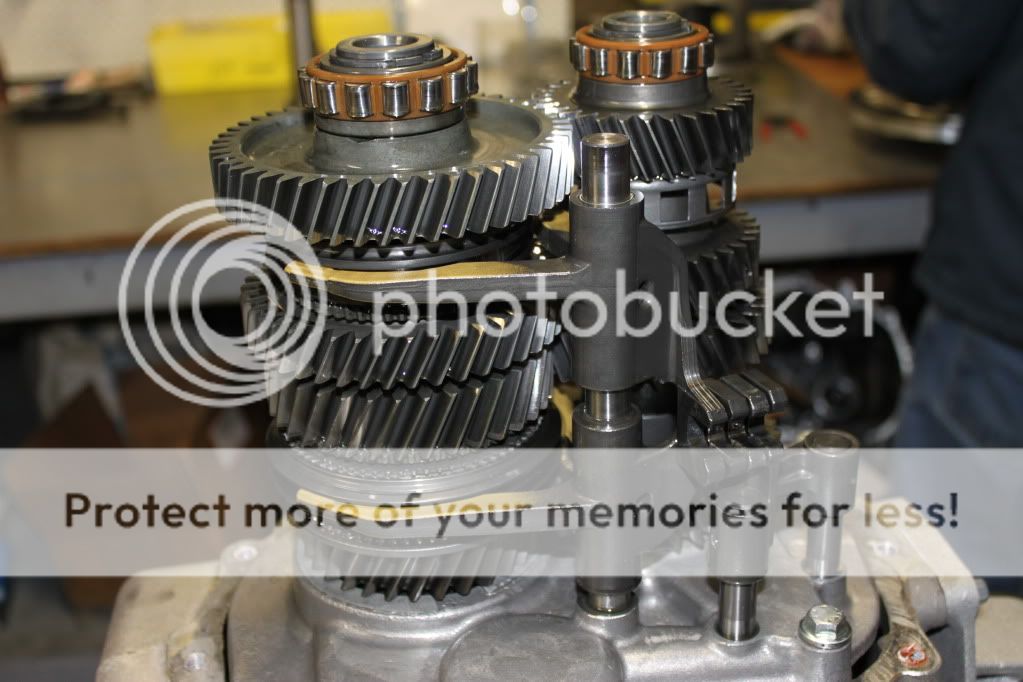

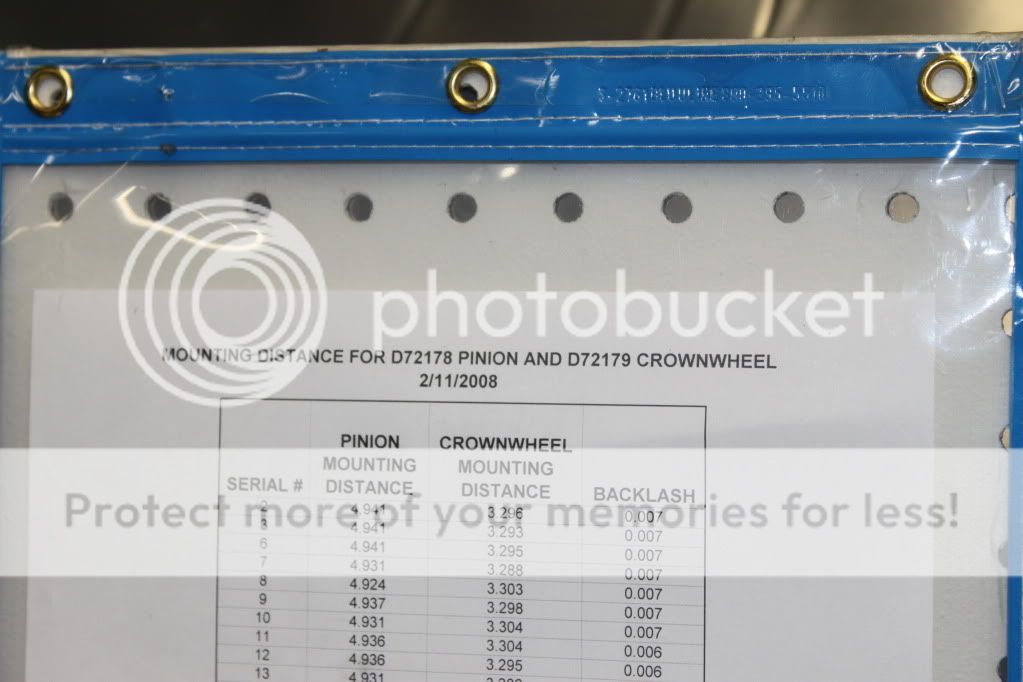

Picture of the 3.90 ring and pinion and associated bearings, and shims.

In 2006 Team STILLEN went to the New Zealand Targa Rally with the now famous orange Ford GT. 2006 was really just a practice year and we only wanted to learn what we could change and what the car would benefit from. During the development of the car Steve Millen spoke directly with many of the engineers from the GT project and learned that during testing there was actually a 3.90 gear ratio developed for the car. We also learned that the main reason the car comes from the factory with the 3.3 is because marketing did not want any of the magazine's messing up the 0-60 times and with the factory gear ratio you don't need to shift until 62 MPH anyways. However, the engineers liked the increased performance of the 3.90.

Well, a couple of years later and after much development with Ricardo, STILLEN became the only company in the world authorized by Ricardo to work on and service the Ford GT transaxle. We worked very closely with Ricardo to develop the 3.90 ring and pinion and after our initial batch came in with a very aggressive cut we had them all sent back out for polishing and grinding to eliminate as much gear whine as possible. Some owner's will notice that some cars (not all) experience a little bit of whine from the factory, the 3.90 is no different. Some cars make the whine, some cars don't.

Part of the development program for the 3.90 included specialized training from the engineer who developed the Ford GT gearbox. He flew in from England and trained our technicians on the ins and outs of the transaxle. How to strip it down, what to look out for, what to be careful of, and how to rebuild it. It was at this time that we learned that we would need to custom fabricate and machine 7 specialized tools in order to properly and safely disassemble the transaxle.

There were 25 sets of ring and pinions made for us. When the initial 25 were sold we went back to Ricardo and asked what it would take to make another 10 and we also asked for a discount as the cost of steel had dramatically gone down. Unfortunately, Ricardo decided they did not want to make them again and required a minimum of 25 pieces, 50% of the money down to start, then another 50% due upon completion and they were going to raise the cost 30%. We did not feel that the market could stand for a 30% mark up on a part that was already pretty pricey. So, unfortunately, for the time being, there are no immediate plans for another production run of ring and pinions.

So, as requested by one of the forum member's. Here are a few pictures of the inside of a Ford GT transaxle. Please keep in mind that I will be posting more pictures over the next couple of days.

To start with: The engineer from Ricardo who trained us on the installation:

Picture of the 3.90 ring and pinion and associated bearings, and shims.

Last edited: